HISTORY

HISTORY

Public Utility/Commercial

to Upscale Residential

The facility is associated with trends in municipal electric generation and distribution, and improved treatment of drinking water in rural America during the 20th century. Completed in 1934 to replace an older power plant, Culpeper’s Municipal Electric Plant was the first such facility funded with federal Public Works Administration (PWA) financing as part of President Franklin D. Roosevelt’s administration’s emphasis on rural electrification.

Culpeper’s plant proved to be an economical and efficient source of electric service. Within its first five years the new plant reduced consumer rates by approximately 10 percent and profited the Town. That success prompted other Virginia municipalities and utility companies to evaluate their rate structures and improve their services. With upgrades over the years, the Culpeper Municipal Electric Plant remained in operation until a new facility on a different site replaced it in 2006.

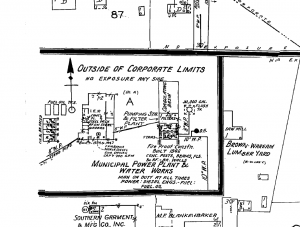

Culpeper’s Waterworks, completed in 1947, incorporated technological advances in water treatment, and adhered closely to revised and expanded water treatment standards issued by the U.S. Public Health Service in 1946. Those standards regulated the bacteriological quality of drinking water and introduced methods for removing disease causing substances and pathogens.

Both the electric plant and waterworks buildings exemplify the era’s Moderne style, as influenced by federal involvement. The PWA’s stringent oversight and regulatory standards for design, engineering, and construction shaped the Electric Plant. The Culpeper Waterworks building continued a federally standardized Moderne style into post-World War II. The red brick facing of both structures matches building materials used historically throughout Culpeper and visually softens the industrial nature of the buildings within their surrounding residential neighborhood.

Both buildings are being renovated into 22 upscale “loft-style” residences. The Culpeper Lofts project is being redeveloped by Echelon Resources, an experienced development team with a long history of success with adaptive reuse projects. This project utilizes both federal and Virginia historic rehabilitation tax credits which require that any significant historic features be preserved and highlighted. The project plans are reviewed in detail and approved by both the Virginia Department of Historic Resources and the National Park Service, with regards to compliance with the U.S. Secretary of the Interior’s Standards for Rehabilitation. Project delivery is expected in Fall 2019. For more information and tours, please Contact Us.

Highlights of the site history prior to this redevelopment project include:

- In 1903, Dr. Orville Nalle and George Major built the first electric power plant in Culpeper – the Culpeper Light and Ice Company. Some years later, this company was purchased by the Virginia Public Service Company (VEPCO/VA POWER). The site of Culpeper Light and Ice Company is close to the site of the current substation at 500 East Chandler Street. In 1933, the Town voters approved a referendum to establish its own power plant and distribution system. The original power plant was established on the site of the Town’s then existing diesel water pumping station which was located on property owned by the Town. The original power house was built around the then existing diesel engine driven pumping equipment so that the same service personnel could operate both groups of equipment. Later, upon construction of the Town’s new water treatment plant, the water pumping equipment was removed from the power house.

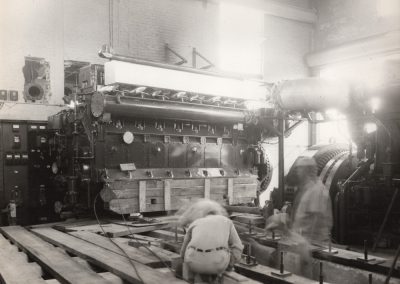

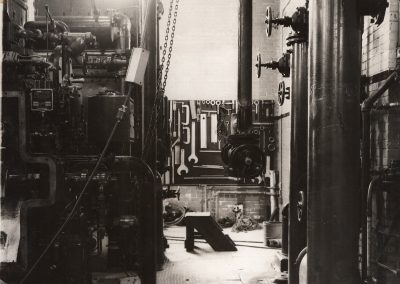

- The original installation consisted of three De La Vergne Engine Co. diesel engine-generator units with the required auxiliaries; which were installed in a brick building with overhead hand operated bridge crane. Space was provided within this original building for the addition of two future generating units. The three original units consisted of two units having a capacity of 270 KW each and one unit having a capacity of 160 KW. The one small unit and one of the large units were required to take care of the initial maximum demand of about 350 KW. The other large unit was initially a standby unit.

The total cost of this initial project, including the electric distribution system, was $158,430. The cost of the power plant portion of the project, including a share of certain general expenses of the Town and professional engineering services, amounted to $17,270 for the power plant building and $97,770 for the mechanical and electrical equipment. This installation was a Public Works Administration project and the Federal Government made an outright grant to the Town of 45% of the $158,430 investment.

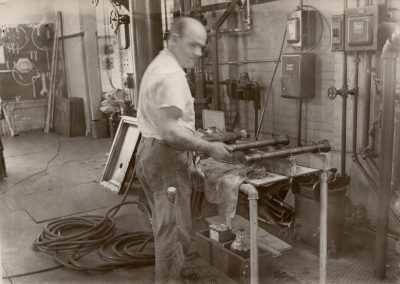

The total plant generating capacity at the time of the original installation was 700 KW, with a safe generating capacity (one of the larger units out of service) of 430 KW. - As a result of certain difficulties being experienced in the use of raw creek water, which was used for engine jacket cooling, a closed cooling water system was installed for the three original engines in 1937 at a cost, including professional engineering services, of $4,533.

- In 1941 the Town purchased a 520 KW capacity diesel engine-generator unit from the Worthington Pump & Machinery Corporation. This unit was installed in one of the spaces previously provided for future units. This unit, complete with auxiliaries, electric wiring, and piping, cost $55,000. The total capacity of the plant after the installation of this unit was 1220 KW, with a safe plant generating capacity (largest unit out of service) of 700 KW.

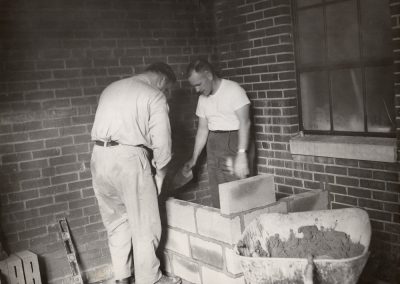

- In 1949 a second addition was completed and placed in operation. The diesel pumping unit for the water system was still in the plant and for this reason this space could not be occupied by the new generating unit. The decision was made to construct an extension to the building for two units, and to provide a wing at the north side of the building for auxiliaries, offices, etc. The work included certain additions to the switchboard, conversion of the primary electric system from 2300 volt Delta to 4160 volt Wye, addition of engine lubricating oil purification equipment, extensive revisions to the power plant electrical facilities in order to insure continuity of service and the provision of evaporative cooler type engine jacket cooling equipment for the new and 1941 diesel engine-generator units. This power plant addition included a diesel engine-generator unit as manufactured by the Nordberg Manufacturing Company, which had a capacity of 855 KW.

- At this time, natural gas service was provided to the power plant and the new engine-generator unit purchased vas of the dual fuel type designed to burn either 100/ diesel oil or as much as 95/ gas and 5/ diesel oil or any intermediate combination of the two fuels. At this time gas equipment was added to the Worthington unit installed in 1941. This installation cost $33,969 for the power plant building addition and $154,840 for the mechanical and electrical equipment. The total capacity of the plant after the installation of this unit was 2075 KW, with a safe plant generating capacity (largest unit out of service) of 1220 KW.

- In 1952 a third engine-generator addition was completed by the Town. The unit was of the dual fuel type manufactured by Nordberg Manufacturing Company, which had a capacity of 920 KW. It was installed in the location formerly occupied by the old diesel pumping unit, which had been removed since the 1949 addition. This installation cost $149,000. The total plant capacity now became 2,995 KW, with a safe capacity (largest unit out of service) of 2,075 KW.

- The 1960 project consisted of the addition of a dual fuel engine-generator unit as manufactured by Nordberg Manufacturing Company, having a capacity of 1220 KW. It was installed in the location of the 160 KW unit, installed in 1934, which was removed at this time. This project included two small building additions at the rear of the power plant; one for lubricating oil equipment and the other for general storage. This installation cost $5,542 for the building additions and $194,854 for the mechanical and electrical equipment. The total plant capacity now became 4055 KW, with a safe capacity (largest unit out of service) of 2835 KW.

The 1965 project consisted of the addition of a dual fuel engine-generator unit as manufactured by Nordberg Manufacturing Company, having a capacity of 1500 KW. It was installed in the location of the middle 270 KW unit installed in 1934, which was removed at this time. The cost of this installation was $240,000. The total plant capacity now became 5016 KW, with a safe capacity (largest unit out of service) of 3786 KW. - In 1974, 2 Solar gas turbine generators were added unit as manufactured by Nordberg Manufacturing Company, having a capacity of 1600 KW. It was installed in the location of the middle 270 KW unit installed in 1934, which was removed at this time. The cost of this installation was $240,000.

- In 1988, Units #1 (1952) & #2 (1941) were removed because they had deteriorated and it was no longer economical to repair them.

- In 1989 an Electric Motor EMD was installed, having a capacity of 2,000 kW.

- On December 11, 1990, Report and Recommendation was approved to build an Electric Utility Complex. On May 10, 1993 the new Chandler street substation was energized with two power transformer located in it and was designed for an ultimate build out of third power transformers. Currently 3 distribution circuits are being used provide power to the town with build out to a total of 9 circuits.

- In the spring of 2002 Town Council approved the building of a new generation facility at the Chandler electric complex. This was in conjunction with extending the wholesale power contract through 2010. The new facility had an estimated cost of $1,400,000.00. The building will include 3 new generators as well as associated automated switchgear for tying the generators to the distribution substation. This new equipment will replace the existing antiquated generation equipment at the Spring Street facility. Construction began in 2004 on the new generation facility. The facility went on line the fall of 2005. Dedication of new generation facility took place February 2006. With the new generation facility coming on line the antiquated generators at the Spring Street facility Units 4,5,6 (Nordbergs) and both turbines (T1&T2) were retired in 2005 due to age and cost of upkeep.

- In 2009 the 2 Solar gas turbine generators that were manufactured by Nordberg Manufacturing Company and installed in 1974 were sold. Emd unit #2 that was installed in 1989 was sold due to the fact it was not cost effective to move to the new generation facility and increasing maintenance cost. The sale price was $90,000.00

- With the decommissioning of Units #4, #5, #6 Norbergs in 2005 the L&P department with the assistance of Enviromental Services department placed the 3 units along with the switch gear on govdeals website. The town received a final price of $10,000 for all the equipment. Work began the first week of March 2015 on the removal.

Redevelopment

The story of the newly-renovated Culpeper Lofts began in the early part of the last century! The historic Culpeper Power and Water Works buildings are comprised of 2 separate structures, the power plant (414 Spring Street) having been dedicated in July 1934 and the Water Works (410 Spring Street) in 1946. Through much planning and creative thinking (and hard work!) the buildings have been renovated into market-rate rental housing – studio and one-bedroom “loft-style” residences – known as Culpeper Lofts. The parking and grounds have also been revamped. The historic features were preserved and highlighted as this project utilized federal and state historic rehabilitation tax credits, so the redevelopment design was overseen by both the Virginia Department of Historic Resources and the federal National Park Service. These upscale apartments maintain many of their original historic features while offering polished concrete and hardwood floors, all-new appliances and systems, high ceilings, beautiful cabinets…and many other amazing features in this pet-friendly community. Come tour your next apartment home!

Project Timeline

- December 2016 | Town leaders introduced to Developer

- August 2017 | Developer submits proposal to Town

- November 2017 | Town unanimously approves purchase contract

- December 2017 | Developer purchases Site from Town

- February 2018 | Town approves rezoning to Planned Unit Development (PUD)

- May 2018 | Site plan approval received from Town

- September 2018 | Zoning permit approval received from Town

- October 2018 | Building permit approvals received from County

- November 2018 | Construction begins

- Fall 2018 | Approvals received from Virginia Department of Historic Resources and the federal National Park Service

- December 2018 | Project construction loan closes

- July 2019 | Construction completed